7075 alloy typical applications

- Aircraft and high strength parts

- Bicycle and motorcycle brake disc or Sprocket (YXD supply thickness tolerance within 1/2 EN485 or 1/2 ANSI)

- Mold tool manufacturing

- Cellphone chassis, medical devices

- Hobby-grade RC models chassis plates

- Other industrial applications

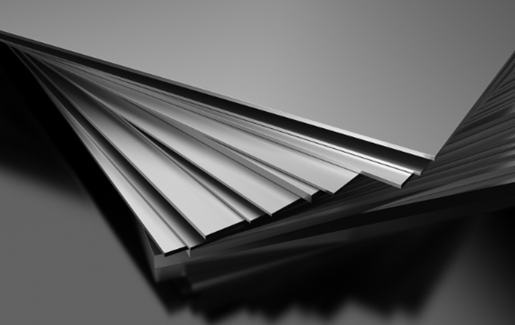

Description:

7075 aluminium is an alloy with zinc as the primary alloying element. It bring excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It’s more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the alloys from the 2000 series. It’s one of the most commonly used aluminium alloys for highly stressed structural applications and has been extensively used in aircraft structural parts.

YXD Supplies

Thickness Range (mm)

0.5~260

Width Range (mm)

500~2600

Ex-mill time, weeks

6~8

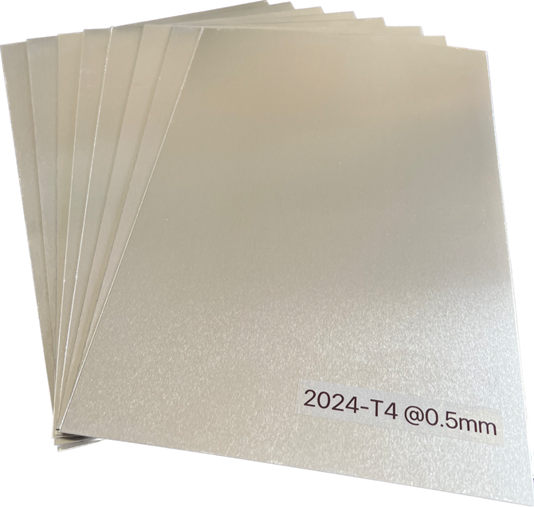

Mechanical Properties

| Alloy | Temper | Thickness(mm) | Width(mm) | Tensile Strength Rm(Mpa) | Yield Strength Rp0.2(Mpa) | Elongation A50%(YXD) | Standard | ||

| Standard | YXD material | Standard | YXD material | ||||||

| 7075 | T6 | 0.5-5.0 | 500-2600 | 540 | 550-570 | 460 | 480-500 | 11-15 | EN485/ASTMB209 (AMS available) |

| T73 | 1.0-5.0 | 500-2600 | 460 | 510-530 | 385 | 427-440 | 12-14 | ||

| T651 | 5-260 | 500-2600 | 540 | 570-590 | 460 | 495-515 | 10-13.5 | ||

| T7651 | 5-260 | 500-2600 | 538 | 550-560 | 462 | 480-490 | 10.5-12.5 | ||

| T7351 | 5-260 | 500-2600 | 476 | 500-520 | 393 | 420-435 | 10-12.5 | ||

- More specifications, pls download our catalog or contact us directly.