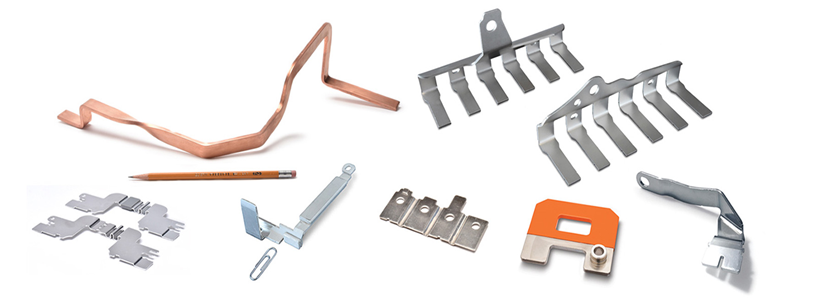

6101 alloy typical applications (>57%IACS)

- Conductor in busbar trunking system

- Busbar in EV(supplying to Tesla)

- Electricity charge pile parts

- Other industrial applications

Description:

6101 alloy is similar to 6063 alloy, but has minor chemistry changes that enhance its electrical conductivity. although slightly lower in conductivity than alloy 1350, it offers greater strength. as a heat treatable wrought alloy, 6101 aluminum is best suited to these applications which require moderate strength and maximum electrical conductivity.

6101 is an excellent choice for bus conductors & electrical projects, because it is only one-third the weight of copper, dissipates heat rapidly, is lightweight but very strong and highly corrosion resistant, and conducts an equal amount of electrical power with only half as much material weight as copper.

YXD Supplies

Thickness Range (mm)

2.0~10

Width Range (mm)

200~1500

Ex-mill time, weeks

3~5

Mechanical Properties

| Alloy | Temper | Thickness(mm) | Width(mm) | Tensile Strength Rm(Mpa) | Yield Strength Rp0.2(Mpa) | Elongation A50%(YXD) | Standard | ||

| Standard | YXD material | Standard | YXD material | ||||||

| 6101 | T61 | 2-10 | 200-1500 | 140 | 177-178 | 105 | 141-143 | 22.5-24 | ASTMB317_B317M-2015 |

| T63 | 2-10 | 200-1500 | 185 | 196-197 | 150 | 173-176 | 15.5-17 | ||

- IACS test result report by SGS download(backlinks). This alloy could be supply in extrusions from our own mill as well.