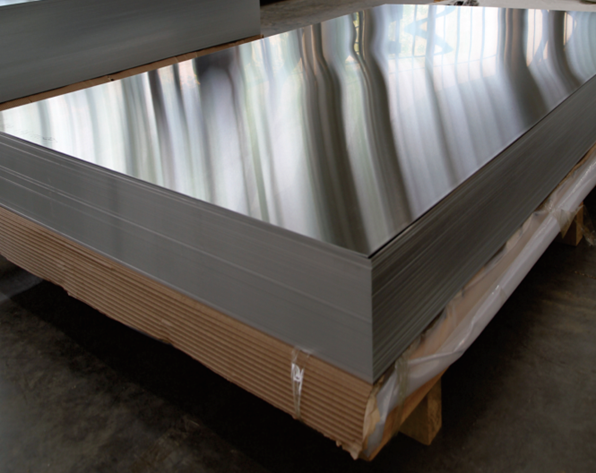

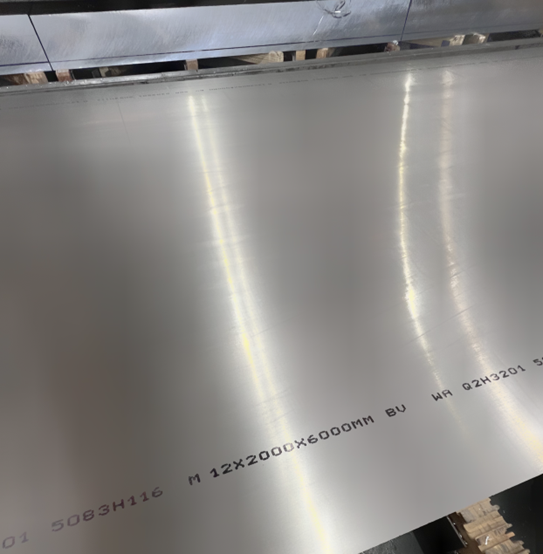

5383 alloy typical applications

- Ship building and offshore constructions (certificated by DNV/BV/LR/CCS/ABS etc, MOQ 2 tons per size)

- Tanker trailer and truck body (quality meet EN 14286:2008).

- Mold tool manufacturing

- Other industrial applications

Description:

Since Zr is added to the 5383 alloy, combine with Al to form an Al3Zr phase, which significantly improve the strength and recrystallization temperature. Therefore, compared with 5083, 5383 bring higher strength and better welding performance. 5383 alloy is an upgraded version of the 5083 aluminum, 5383 marine grade get better corrosion resistance and its hardness has also increased by 10%. These improvements reduce the number of welds. The yield point of the welded structure has increased by 15%.

YXD Supplies

Thickness Range (mm)

2.0~40

Width Range (mm)

500~2600

Ex-mill time, weeks

6~8

Mechanical Properties

| Alloy | Temper | Thickness(mm) | Width(mm) | Tensile Strength Rm(Mpa) | Yield Strength Rp0.2(Mpa) | Elongation A50%(YXD) | Standard | ||

| Standard | YXD material | Standard | YXD material | ||||||

| 5383 | H111 | 2-40 | 500-2600 | 290-360 | 315-330 | 145 | 180-190 | 20-22 | EN485/ASTMB209,B928 EN14286:2008 |

| H112 | 2-40 | 500-2600 | 290 | 315-330 | 145 | 180-190 | 21-23 | ||

| H116 | 2-40 | 500-2600 | 305 | 366-370 | 220 | 245-255 | 22-23 | ||

| H321 | 2-40 | 500-2600 | 305 | 360-375 | 220 | 248-256 | 20-22 | ||

- More specifications, pls download our catalog or contact us directly.