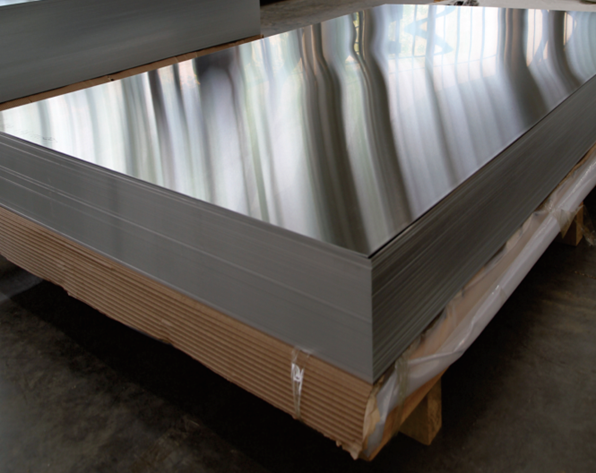

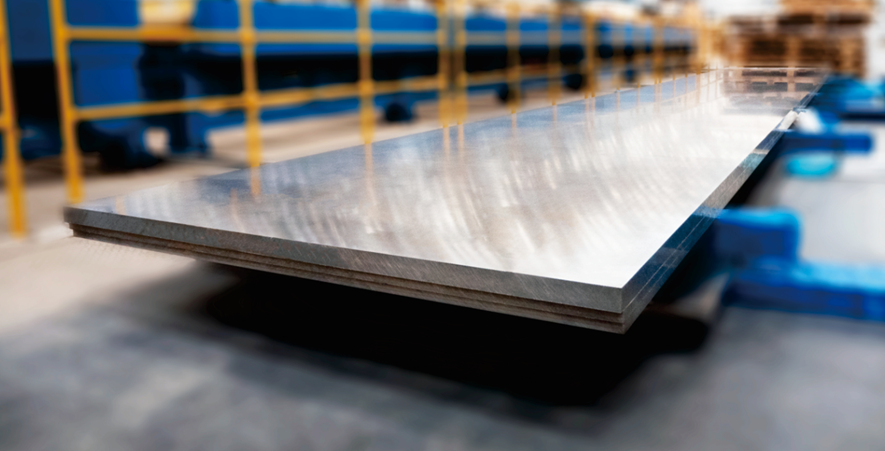

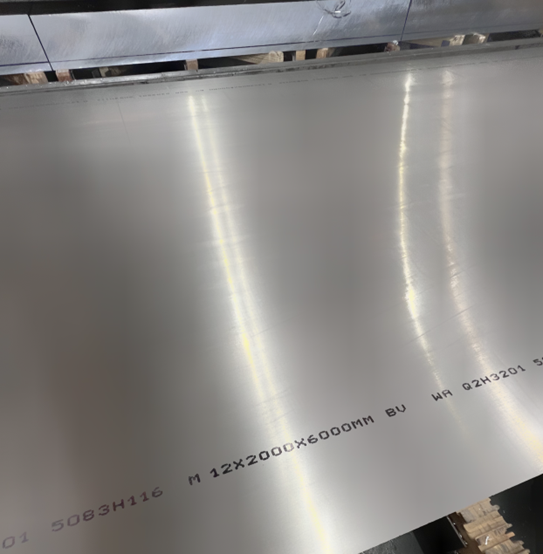

5083 alloy typical applications

- Ship building and offshore constructions (certificated by DNV/BV/LR/CCS/ABS etc, MOQ 2 tons per size)

- Tanker trailer and truck body (quality meet EN 14286:2008).

- Mold tool manufacturing

- Pressure vessels

- Other industrial applications

Description:

5083 is an aluminium–magnesium alloy with magnesium and traces of manganese and chromium. highly resistant to attack by seawater and industrial chemicals. It has the highest strength of the non-heat treatable alloys, together good weldability. 5083 is also commonly used in cryogenic applications because it being able to be cooled to -195° C. at this temperature, the alloy has an increase in ultimate tensile strength of 40% and in yield strength of 10% as well as exhibiting excellent fracture toughness.

YXD Supplies

Thickness Range (mm)

2.0~200

Width Range (mm)

500~2600

Ex-mill time, weeks

6~8

Mechanical Properties

| Alloy | Temper | Thickness(mm) | Width(mm) | Tensile Strength Rm(Mpa) | Yield Strength Rp0.2(Mpa) | Elongation A50%(YXD) | Standard | ||

| Standard | YXD material | Standard | YXD material | ||||||

| 5083 | H111 | 2-40 | 500-2600 | 275-350 | 301-305 | 125 | 170-175 | 21.5-22 | EN485/ASTMB209,B928 EN14286:2008 |

| H112 | 2-40 | 500-2600 | 275 | 301-305 | 125 | 170-175 | 21.5-22 | ||

| H116 | 2-40 | 500-2600 | 305 | 325-327 | 215 | 227-238 | 19.5-21.5 | ||

| H321 | 2-40 | 500-2600 | 305 | 320-321 | 215 | 229-240 | 20-21 | ||

- More specifications, pls download our catalog or contact us directly.