3005 super wide coated coil applications

- Sidewall skin of bus/trailer/van/ Recreational vehicle(RV)

- Automotive parts

- Skin of aluminum composite panel, sandwich panel

- Decorative applications of buildings, trains

- Other industrial applications

Description:

3005 is an aluminum alloy with manganese as its primary alloying element, supplemented with a magnesium addition which makes it stronger than 3003 alloy, It’s commonly rolled in coils or sheet for applications such as automotive parts, construction materials and others.

3005 coated coils also called 3005 pre-painted coils, which bring bared aluminum colorful appearance and endurance. YXD contribute to supply this material for the applications which face outdoor challenges.

with a chemical pretreatment (cleaning) firstly, rear side coated by adhesive epoxy and priming on front side then topcoat layers with polyester(PE),PVDF or Acrylic. The polyester coatings belong to the highly weather-resistant systems with simultaneously high ductility and flexibility. UV resistance performance of PVDF coating absolutely better.

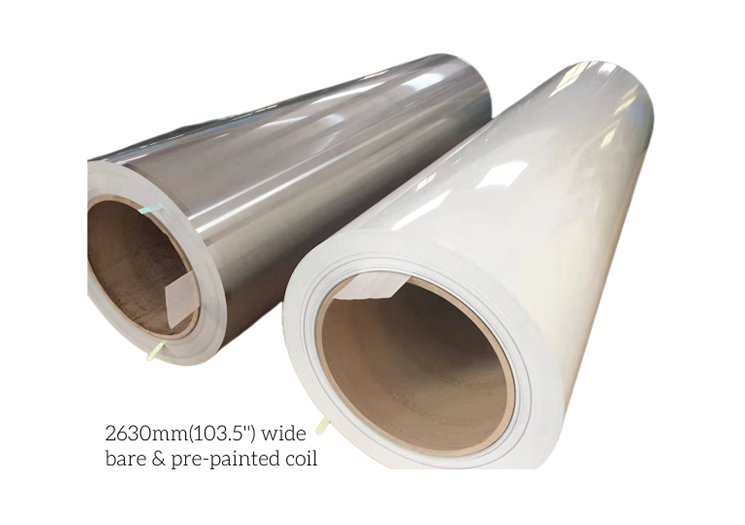

Our 3005 pre-painted coil and sheet width up to 2650mm(104 inch), fully meet EN1396-2015, only top-quality bare metal and coating material from Akzo Nobel/PPG are preferred by us.

YXD Supplies

Thickness Range (mm)

0.04~3.0

Width Range (mm)

900~2650

Ex-mill time, weeks

8~10

Typical capability (coil & sheet):

| Typical aluminum coated coil & sheet capability | Standard | |||

| Alloy | Thickness range(mm) | Width range(mm) | Coating material | |

| 3003 | 0.04 to 3.0 | 900 to 2650 | PE, PVDF, FEVE, Epoxy | EN1396-2015 |

| 3005 | 0.04 to 3.0 | 900 to 2650 | PE, PVDF, FEVE, Epoxy | |

| 5005 | 0.04 to 3.0 | 900 to 2650 | PE, PVDF, FEVE, Epoxy | |

| 5052 | 0.04 to 3.0 | 900 to 2650 | PE, PVDF, FEVE, Epoxy | |

| 5754 | 0.04 to 3.0 | 900 to 2650 | PE, PVDF, FEVE, Epoxy | |

| Remarks: double sides both coated, color customized and protective film available | ||||

- All coils/sheets could be supply in bare ones. more specifications, pls contact us directly