2219 alloy typical applications

- Rockets and missile parts

- Aerospace fuel tanks

- Aircraft skin and structural components

- Other industrial applications

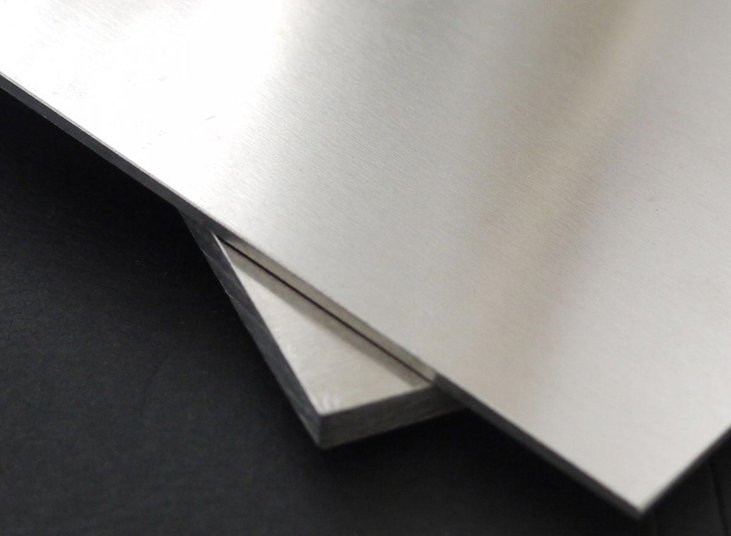

Description:

2219 aluminium alloy can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys get high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys.

This alloy in particular has high fracture toughness, is weldable and resistant to stress corrosion cracking, therefore it is widely used in supersonic aircraft skin and structural members. The Space Shuttle Standard Weight Tank was also fabricated from 2219 alloy.

YXD Supplies

Thickness Range (mm)

4.0~260

Width Range (mm)

1200~3800

Ex-mill time, weeks

8~12

Mechanical Properties

| Alloy | Temper | Thickness(mm) | Width(mm) | Tensile Strength Rm(Mpa) | Yield Strength Rp0.2(Mpa) | Elongation A50%(YXD) | Standard | ||

| Standard | YXD material | Standard | YXD material | ||||||

| 2219 | T6 | 4-260 | 1200-3800 | 425 | 430-450 | 315 | 350-365 | 11-16.5 | ASTMB209 (AMS available) |

| T62 | 4-260 | 1200-3800 | 370 | 420-430 | 250 | 285-330 | 14-15 | ||

| T87 | 4-260 | 1200-3800 | 440 | 450-475 | 350 | 360-390 | 8-13.5 | ||

- More specifications, pls download our catalog or contact us directly.